Norden launches NC100 cartoner at Fachpack 2025

publié le vendredi 12 septembre 2025

Coesia will showcase a strong line-up of solutions at Fachpack 2025, taking place from September 23 to 25 at Nürnberg Messe. A highlight will be the introduction of Norden’s new NC100 cartoner, reinforcing the company’s leadership in advanced tube filling and packaging solutions. Visitors will discover how Coesia companies are advancing automation across consumer, healthcare, and industrial sectors with scalable and sustainable systems. Experts from FlexLink, AMACO, Norden, and Volpak will be present at the booth, showcasing technologies that enhance efficiency, flexibility, and long-term value creation.

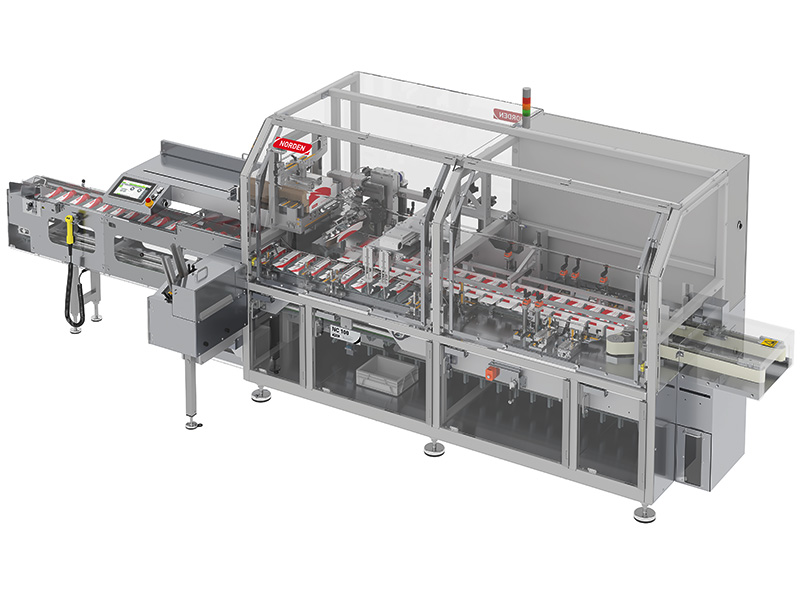

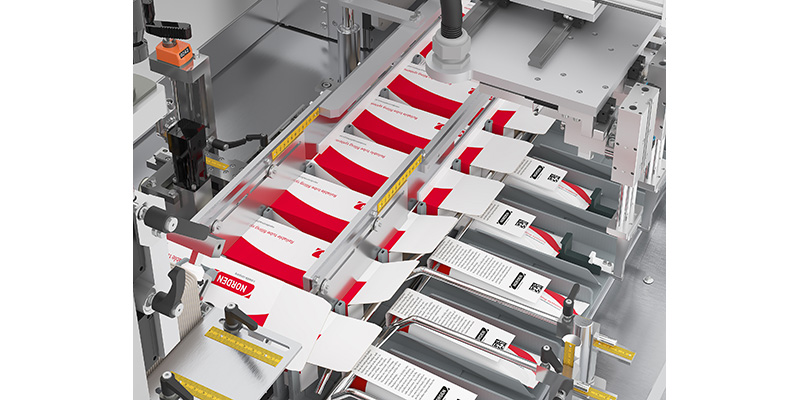

Norden’s newly launched NC100 cartoner is designed to maximize operational efficiency and flexibility in pharmaceutical, personal care, food, and consumer packaging environments. Handling up to 100 cartons per minute, the NC100 offers fast and repeatable changeovers with up to 50 preprogrammed formats accessible at the touch of a button. Ergonomic material loading, intuitive EasyWare II software, and a 10-inch touchscreen HMI simplify daily operations and reduce training requirements, ensuring optimal user experience.

Built on a balcony-type design for easy access and cleaning, the NC100 combines mechanical robustness with servo-driven precision. Its flexibility extends to carton erection, leaflet insertion, coding with inkjet or laser, and multiple carton closure options, delivering both functional and tamper-evident packaging. OCR/OCV and barcode scanning can be integrated to ensure compliance with demanding pharmaceutical standards. These features translate directly into economic advantages for customers: reduced downtime, lower operating costs, faster format adaptation, and consistently high product quality throughout the machine lifecycle.

Alongside the NC100, Norden will present the proven NM902 tube filler, capable of handling up to 100 tubes per minute across a wide variety of materials, including plastics, laminates, metals, and sustainable mono-materials. Its flexibility enables options like swirl or three-color filling, while its clean design makes it suitable for cleanroom environments. Serving industries such as personal care, pharmaceuticals, healthcare, chemicals, food, and home care, the NM902 delivers high efficiency and reliability, giving manufacturers the ability to adapt quickly to new market and sustainability requirements.

Together, the NM902 and NC100 form a complete line that combines speed, adaptability, and automated precision. This setup enables manufacturers to achieve higher throughput, minimize waste, and reduce total cost of ownership.