Hosokawa Alpine unveils its solutions at K2025 in blown film production

publié le jeudi 09 octobre 2025

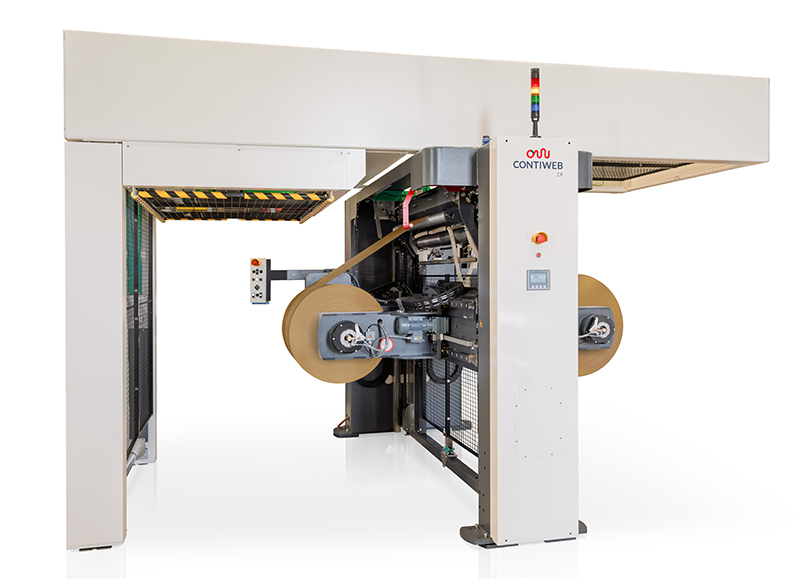

Hosokawa Alpine AG presents its range of services for the production of blown films at the K 2025 trade fair in Düsseldorf from 8 to 15 October 2025 under the motto ‘Blown film in perfection’. The presentation focuses on the flexible 9-layer system from the Augsburg-based mechanical engineering company.

Thanks to its unique adaptability, it gives customers the freedom to master future market requirements innovatively and confidently. With solutions for the production of sustainable full PE films and films made from PCR materials, Hosokawa Alpine is also addressing the major trade fair theme of ‘Shaping the circular economy’. The company’s recycling division will be showcasing its technologies, including those for recycling PCR plastics and films.

Hosokawa Alpine has developed a solution for changing the stretching roller that takes only 15 minutes. Quick changeover ensures permanent availability of your system, flexibility in the selection of stretching rollers and thus maximum productivity. In addition to this quick roller changeover, Hosokawa Alpine will also offer ultrasonic bath cleaning for vacuum rollers.

Hosokawa Alpine will also be focusing on its wide range of automation and digitalisation solutions at the trade fair. These include the ExVis process visualisation system with its start-up assistant, which allows a plant to be started up in just four steps, and its one-touch change for quick switching between film formats. The company’s service brand, Blueserv, offers a new solution for predictive maintenance with isa.guard. It combines continuous sensor data with expert analysis to detect anomalies in real time and enable proactive maintenance planning.

Blown film lines are just one of Hosokawa Alpine’s many areas of business. In the field of mechanical process engineering, the mechanical engineering company specialises in recycling technologies, among other things. Here too, Hosokawa Alpine will be presenting innovative solutions for various materials at K 2025. These include plastics such as film residues and PCR materials, as well as rubber and textiles. The Rotoplex cutting mill plays a key role in many applications.