A modular small batch solution for liquid pharmaceuticals

publié le vendredi 30 avril 2021

There has been a noticeable shift in the pharmaceutical industry: more and more high-priced biotech drugs for small patient populations require highly flexible filling solutions that achieve precise product yields at low output.

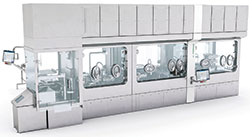

Accordingly, has developed a new portfolio: the company now bundles solutions for small and micro batch applications under the name. The new, modular small batch solution (Flexible Filling Platform) is an individually configurable machine with an integratable isolator for filling aseptic and highly potent liquid active ingredients. « We offer pharmaceutical manufacturers, R&D laboratories and biotech startups a combination of standardization and high modularity with short delivery times, » says Klaus Ullherr, senior product manager at Syntegon. The platform is based on pre-developed and tested modules that can be flexibly combined. Versynta FFP processes up to 3,600 containers per hour and comes with 100% in-process control.

Versynta FFP can be easily converted to different container types such as vials, syringes, and cartridges, as well as different filling systems including single-use solutions. Instead of entire modules, only format parts need to be replaced, which have also been kept to a minimum. In addition, the platform offers the possibility of vacuum-free high-potent vial processing. The Pharma Handling Unit, a four-axis robot developed by Syntegon, allows for safe and gentle transport. It transfers the containers from one station to the next without glass-to-glass contact. The laminar flow-optimized design ensures that the air flow can reach the containers and flow around them without obstruction (« first air supply »). Versynta FFP is suitable for filling both aseptic and highly potent products with short cycle times. International pharmaceutical company Ferring Pharmaceuticals is working on the first installation of Versynta FFP with Syntegon.

Versynta FFP can be easily converted to different container types such as vials, syringes, and cartridges, as well as different filling systems including single-use solutions. Instead of entire modules, only format parts need to be replaced, which have also been kept to a minimum. In addition, the platform offers the possibility of vacuum-free high-potent vial processing. The Pharma Handling Unit, a four-axis robot developed by Syntegon, allows for safe and gentle transport. It transfers the containers from one station to the next without glass-to-glass contact. The laminar flow-optimized design ensures that the air flow can reach the containers and flow around them without obstruction (« first air supply »). Versynta FFP is suitable for filling both aseptic and highly potent products with short cycle times. International pharmaceutical company Ferring Pharmaceuticals is working on the first installation of Versynta FFP with Syntegon.

Part of 655 issue – February 21. All rights reserved except agreement written by Emballage Digest or mention of the magazine