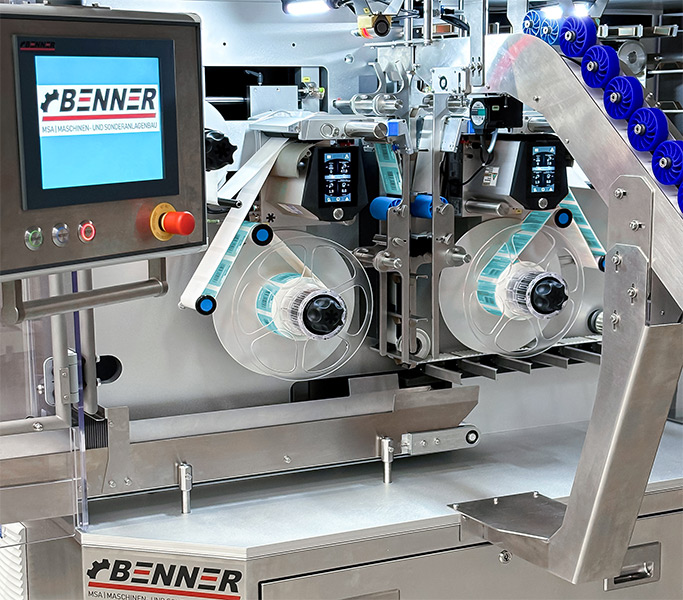

Benner MSA chooses Herma label applicators for multipack application

publié le mercredi 12 mars 2025

Benner MSA uses Herma label applicators in one of the first multipack machines for medium-sized quantities, e.g. for bags containing nuts, dried fruit and so on. The flexible, space-saving machine bundles bags into 20 to 30 multipacks per minute, offering an efficient alternative to costly manual work. The Herma label applicators were configured online in order to achieve the compact dimensions and the required precision using standard modules.

Multipacks are popular with consumers and lucrative for retailers. However, there are hardly any suitable machines to support this process for medium-sized quantities that are simply held together with labels to save material. To fill this gap, machine builder Benner MSA has developed a compact system equipped with Herma 500 label applicators. This multipack machine has a footprint of no more than four square metres and is ideal for situations where an upstream packaging system operates at around 60 to 80 work cycles.

« There are, of course, one or two other manufacturers of label-based multipack machines. However, these machines are single-format systems designed for a single product that is produced in extremely high volumes, such as a well-known biscuit snack, » says Ilyas Zorla, Managing Director of Benner MSA, based near Karlsruhe, Germany. « These machines are not only very large, they are also very, very fast and can easily run at 700 cycles per minute. » The Benner MSA machine, on the other hand, bundles bags into 20 to 30 multipacks per minute. « For many suppliers of, for example, nuts, dried fruit, cereal bars and so on, this processing speed is perfectly adequate – here a higher output would be uneconomical. »

Together with Herma, Benner MSA has developed a label-based multipack machine for « mid-range » products. In this new type of system, the individual, ready-filled bags are transported up a sloping conveyor belt to a height of about two meters. There the bags are fed into a compartmentalized conveyor belt where each compartment receives a defined number of horizontally positioned bags. Two Herma 500 label applicators, one on each side, then apply a pre-perforated label to form the multipacks. As standard, the machine is designed for bags measuring around 65 x 150 x 25 millimeters (W x L x H). However, the machine is flexible enough to allow wider products to be bundled. The four side guides of the shaft in which the bags are located can be adjusted to any dimension.

In addition to its specific output and flexibility, the Benner MSA machine is characterized by its outstanding precision: To ensure that the individual bags can be easily separated, the perforations must be positioned exactly at the « gaps » between the bags. The Herma 500 has an additional advantage: The label applicator was designed together with the machine manufacturer Benner MSA in real time in the Herma online configurator in such a way that an extremely compact design could be realized.

Another advantage of the new multipack machine: It can easily process irregularly shaped bags. For example, peanuts and cashews are dry and hard, while dates and cranberries are soft and pliable. And depending on the product, the bag contains different amounts of air. This can be as much as five millimeters high.