Berry’s introduces 30% recycled plastic content in stretch hood film

publié le mardi 14 février 2023

Berry Global’s flexible films division is launching a next generation version of its proven stretch hood film with a minimum 30% recycled plastic content. This will help to support businesses in achieving their own sustainability objectives as well as meeting the requirements of current and forthcoming UK and European plastics packaging legislation.

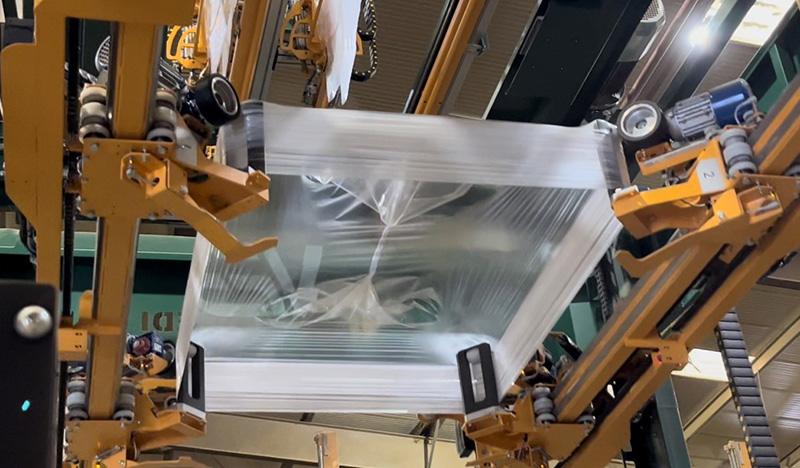

Stretch hood film stretches over and around a pallet of finished goods, providing improved load stability and full waterproofing for the load, with much lower material usage than traditional shrink hooding films. However, it is the demanding stretch requirements of the film that make the inclusion of any level of recycled material in its manufacture extremely challenging, particularly in terms of impeding the overall stretch capability.

Berry’s Sustane® polymers incorporate recycled plastic with the objective of delivering high levels of technical performance, consistency, traceability and quality. In particular, the incorporation of Sustane® into the stretch hood film has been achieved while maintaining reliable seal integrity and high tear resistance. This ensures effective product protection throughout the supply chain.

The new Stretch Hood Sustane® film containing a minimum 30% recycled content is particularly ideal for low to medium stretch applications in markets such as beverages, building and glass. It is being manufactured in Berry factories in Belgium, Germany, Poland and the UK, offering localised supply and support to businesses and brands of all sizes. Berry has calculated that the recycled content film can deliver a reduction in carbon emissions of around 18% compared to one produced entirely from virgin material*. Importantly it can also be used on existing stretch machinery.

“Stretch Hood Sustane® provides the perfect opportunity for customers to access a pallet stretch hooding solution where previously only prime polymer versions were available,” said Daniel Stauber, Commercial Director, Berry Packaging Solutions Industrial. “It is another example of our commitment to help customers meet and exceed their sustainability goals.”

*Calculated using CF (Climate and Forecast) data on virgin and recycled PE from several peer reviewed publications from American Chemical Council published in 2020.